-

DIN 1.2083 Steel, 1.2085 mould steel, 1.2085 Steel, 1.2316 MOLD STEEL PLATES, 2316 Corrosion Resistance Plastic Mold Steel, 2316 STEEL PLATES, Corrosion Resistance ESR Plastic Mould Steel, Corrosion Resistance Steel, ESR GRADE STEEL, High Hard Plastic Mould Steel, Mirror Finish Mould Steel, Mould Steel, P20 Steel, Plastic Mold Steel, Plastic Moulds Steel, Stainless Steel for Plastic Injection Molds, Tool Steel for Plastic Moulds, Tools and alloys Steel

DIN 1.2083 ESR equivalent to STAVAX ESR stainless steel, AISI 420 Steel

There is no AI review summary.Quick View -

DIN 1.2083 ESR, 1.2085 mould steel, 1.2085 Steel, 1.2316 MOLD STEEL PLATES, 2316 Corrosion Resistance Plastic Mold Steel, 2316 STEEL PLATES, Corrosion Resistance ESR Plastic Mould Steel, Corrosion Resistance Steel, DIN 1.2083 Steel, ESR GRADE STEEL, High Hard Plastic Mould Steel, Mirror Finish Mould Steel, Mould Steel, Plastic Mold Steel, Plastic Moulds Steel, Rubber Moulds Steel, Stainless Steel for Plastic Injection Molds, Steel For Paver Moulds, Tool Steel for Plastic Moulds, Tools and alloys Steel

DIN 1.2083 ESR Steel, AISI 420 ESR Steel, X40Cr14 ESR Steel, and XY2Cr13 ESR Steel Supplier in India

There is no AI review summary.Quick View -

1.2085 mould steel, Corrosion Resistance Steel, DIN 1.2083 Steel, Mirror Finish Mould Steel, Mould Steel, Plastic Mold Steel, Plastic Moulds Steel, Rubber Moulds Steel, Stainless Steel for Plastic Injection Molds, Tool Steel for Plastic Moulds, Tools and alloys Steel

DIN 1.2083 Steel,STAVAX ESR, AISI420, X42Cr13, SUS420J2

There is no AI review summary.DIN 1.2083 Steel Plastic mould Steel especially developed for transparent and mirror finish plastic mold. equivalent to STAVAX ESR, AISI420, X42Cr13, SUS420J2

Quick View -

1.2085 mould steel

DIN 1.2085 stainless Steel Plastic mould Steel

There is no AI review summary.Usage/Application

Automobile IndustryMaterial

Mould Steel Din 1.2085Surface Finish

polishedDimension

customizedDensity

customizedShape

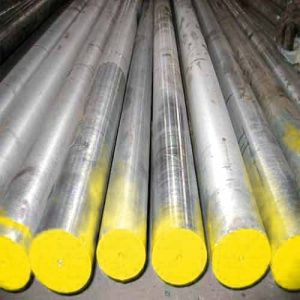

RoundQuick View -

1.2085 mould steel, 1.2085 Steel, Corrosion Resistance ESR Plastic Mould Steel, Corrosion Resistance Steel, ESR GRADE STEEL, High Hard Plastic Mould Steel, Mirror Finish Mould Steel, Mould Steel, Plastic Mold Steel, Plastic Moulds Steel, Rubber Moulds Steel, Stainless Steel for Plastic Injection Molds, Steel For Paver Moulds, Tool Steel for Plastic Moulds, Tools and alloys Steel

DIN 1.2085 Steel, The Ultimate Corrosion-Resistant Plastic Mold Steel

There is no AI review summary.Quick View -

1.2085 mould steel

DIN 1.2311 mold steel

There is no AI review summary.1. Supply Range of 1.2312 Material

Round Bar: diameter 20mm – 500mm

Steel Plate and Steel Block: thickness 12-300mm x width 200-2300mm (*20-120mm plate in stock in prehardened condition)

Surface Finish:…

Quick View -

1.2085 mould steel

DIN 1.2344 Hot work steel

There is no AI review summary.DIN 1.2344 tool steel (also known as AISI H13 steel or just H13) is a tool steel grade standardised for hot working. The main feature of this grade is the combination of…

Quick View -

-

-

1.2085 mould steel

EN 24 steel round | 200mm | best steel stockholder.

There is no AI review summary.Quick View -

1.2085 mould steel

EN41B Nitriding Steel | DIN 1.8509-Steel

There is no AI review summary.Quick View -

1.2085 mould steel, 1.2085 Steel, H 13 Hot Die Steel, H13 TOOL STEEL/DIN 1.2344 STEEL, Hot Die Steel, Hot Work Tools Steel, Tools and alloys Steel

H13 ESR Grade Steel exclusive range buy in Delhi, Manesar, Gurugram, Faridabad

There is no AI review summary.H13 ESR Grade Steel

H13 ESR grade is used mainly for Aluminum Pressure Die Casting & in components where we have high working temperatures and high pressure strength. H13 has high toughness and…

Quick View