EN 31 Alloy steel | SAE 52100 | Best Mechanical Properties.

- Description

- Size Guide

Description

EN 31 Alloy steel | SAE 52100 Steel | Best Mechanical Properties.

Buy EN 31 Alloy steel Round, EN31 Plate, EN-31 Flat in Delhi, Gurugram, Manesar.

It contains 1% Carbon and 1% chromium alloy.

we are leading suppliers of forged and rolled EN 31 alloy steel round rods.

EN-31 alloy steel forging material is available in a wide range.

With manufacturing revel in, strict manage EN31 alloy steel chemical composition and EN31 alloy steel mechanical residences.

From casting, forging, metal to the hot and bloodless rolling method, heat treatment, and so on.

We have the manipulation of professional engineers.

EN 31 STEEL Chemical Composition

| CHEMICAL NAME | REQUIRED RANGE IN % |

|---|---|

| Carbon | 0.90-1.20% |

| Manganese | 0.30-0.75% |

| Chromium | 1.00-1.60% |

| Sulphur | 0.050% max |

| Silicon | 0.10-0.35% |

| Phosphorous | 0.050% max |

It is good quality steel for wear-resisting machine parts and for press tools that do not merit a more complex quality.

We have advanced precision machining gadgets, according to the requirements of customers machining.

A good way to acquire maximum happiness with the person’s requirements.

Forging.

Forge at 1000°/1051°C.

Heat lightly, allowing sufficient time at the forging temperature for the steel to be thoroughly soaked through.

Re-heat as often as necessary to keep the temperature above 850°C.

After forging cool very slowly, preferably in a furnace.

The hardening process of EN 31 Alloy steel.

Heat uniformly to 800/821°C until heated through.

Allow 30 minutes per inch of the ruling section and quench immediately in oil.

Stress Relieving process of EN 31 Alloy steel.

If machining operations have been heavy or if the tool has an unbalanced section.

remove stresses before hardening by heating up to 700°C, equalizing, then cooling slowly.

Annealing of the EN 31 Alloy steel.

Heat uniformly to 801°C, equalize, then the furnace cools. (Hardness about 230 Brinell).

MECHANICAL PROPERTIES.

En31 alloy metallic mechanical properties, our manufacturing is completely in step with the en31 alloy steel standards to satisfy the en31 alloy steel mechanical performance.

also can be in line with the consumer request, to fulfill the requirements of customers of en31 alloy steel mechanical properties.

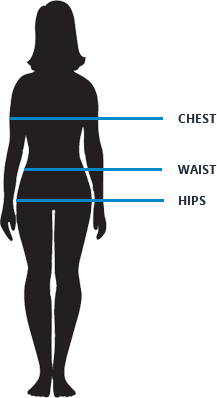

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |