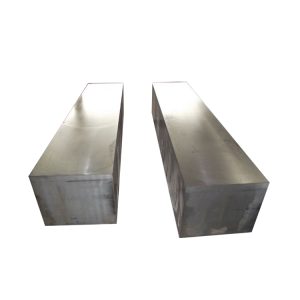

P20 mold steel | pre-hardened | amazing quality Steel for plastic moulds.

- Description

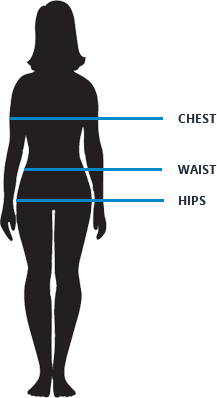

- Size Guide

Description

P20 mold steel a pre-hardened grade steel. An amazing quality Steel for plastic moulds.

P20 mold steel intro.

P20 mould steel is a versatile, low-alloy tool steel that is characterized by good sturdiness at slight strength degrees.

They usually use the steel for plastic injection mold cavities and tooling and for die casting dies for zinc.

They typically buy p20 within the pre-hardened condition at a hardness of approximately 299 hbw.

ANNEALING.

Heat at a rate not exceeding 401°F per hour to 1450°F, and hold at temperature for 1 hour per inch (25.3mm) of maximum thickness; 2 hours minimum.

Then cool slowly with the furnace at a rate not exceeding 50ºF per hour to 1150ºF. Continue cooling to ambient temperature in the furnace or in the air.

P20 Steel Chemical Compositions as per international standard.

| Chemical Name | Available Quantity in % |

|---|---|

| Carbon | 0.28 ~ 0.40 % |

| Chromium | 1.40 ~ 2.0 % |

| Iron | Balance |

| Manganese | 0.60 ~ 1.0 % |

| Molybdenum | 0.30 ~ 0.55 % |

| Silicon | 0.20 ~ 0.8 % |

| Phosphorus | 0.030 max |

| Sulphur | 0.030 max |

pre-hardened P20 mold steel benefits.

- pre-hardened P20 mold steel Reduce tooling production time.

- reduce machining/labor costs.

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |

Related Products

Corrosion Resistance ESR Plastic Mould Steel, Corrosion Resistance Steel, ESR GRADE STEEL, High Hard Plastic Mould Steel, Mirror Finish Mould Steel, Mould Steel, Plastic Moulds Steel, Rubber Moulds Steel, Steel For Paver Moulds, Tool Steel for Plastic Moulds, Tools and alloys Steel

2316 Steel grade is a Premium Quality Mold Steel

DIN 1.2738, High Hard Plastic Mould Steel, Mirror Finish Mould Steel, Mould Steel, P20 Steel, Plastic Mold Steel, Plastic Moulds Steel, Rubber Moulds Steel, Steel For Paver Moulds, Tool Steel for Plastic Moulds, Tools and alloys Steel