DIN 1.2316 Steel 41mm round bar, best PET preforms mold steel, corrosion resistance

- Description

- Size Guide

Description

DIN 1.2316 Steel 41mm round bar best PET preforms mold steel corrosion resistance.

Buy DIN 1.2316 steel 41mm round bar the best quality corrosion resistance PET preforms mold steel.

1.2316 plastic mold tool steel, supplied from stock in rounds, flats, and plates.

DIN 1.2316 steel is chrome-molybdenum steel with improved corrosion resistance properties.

DIN 1.2316 possess good polish ability, toughness, heat resistance, and wear-resistant properties.

It is often used as a tool for processing PVC and chemically aggressive plastic materials.

1.2316 is martensitic stainless chromium steel with uniform hardness in all dimensions.

It is easy to machine, has a high surface finish, and polish ability.

1.2316 is commonly used for plastic molds, and offers a higher corrosion resistance than DIN 1.2083 STEEL.

It can be used for the manufacturing of chemically aggressive materials like PVC and plastics containing abrasive fillers.

We can deliver DIN 1.2316 in the pre-hardened condition (300HB or 340HB).

This grade is not suitable for nitriding and chrome plating because of the high chrome content.

Chemical Composition of DIN 1.2316 steel 41mm round bar.

[table “125” not found /]

1.2316 steel Typical applications:-

best for making PET preforms mold, injection mold for plastic parts, die-casting molds, molding of corrosive material (PVC), and extrusion tools.

HEAT TREATMENT OF DIN 1.2316 STEEL:-

DIN 1.2316 STEEL Already pre-toughened; usually, no heat treatment is required.

Soft annealing:-

760 to 800 °C for about 4 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 650 °C; further cooling in air, max. 230 HB.

Hardening:-

1030 to 1050 °C 15 to 30 minutes keeping curing temperature quenching in water/oil obtainable hardness: 49 HRC

Tempering:-

Slow heating to tempering temperature immediately after hardening.

Minimum time in the furnace: 1 hour per 20 mm part thickness.

Most common Applications :

best for making PET preform mold.

plastic piping molds.

Plastic plumbing injection molds.

making Molds for chemically aggressive plastic substances, etc.

All kinds of silicon steel sheets and high-speed blanking die. Precise stamping die.

Cold extruding forming die.

Cavitations Molds.

Standard Mould Base.

Compression Mould for SMC.

PET blowing mould.

Surface Option available:-

- Black Surface.

- Grinded steel surface: Bright but rough; Size Not precision.

- Machining for plate: Bright and precision; Little turning scar.

- Peeled/Turned: Bright and precision; Little turning scar.

- Polished: Very Bright and precision size; Not turning scar.

Other Services We offer you:-

- Cutting: Small pieces.

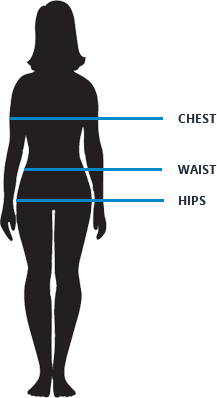

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |