M35 Steel Round Bar | DIN 1.3243 | JIS SKH55 | Extraordinary Physical Properties.

- Description

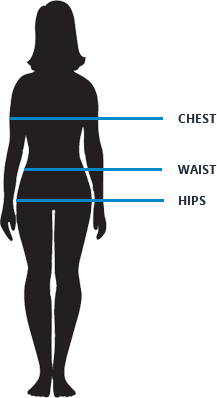

- Size Guide

Description

M35 Steel Round Bar | DIN 1.3243 | JIS SKH55 | Extraordinary Physical Properties.

M35 Steel Round Bar:-

It also is called skh55 steel and 1.3243 steel.

M35 steel is high speed tool steel. After the warmth remedy, its hardness, pink hardness and put on resistance may be improved. And the hardness can up to sixty seven-71hrc.

It is a superb fabric for making equipment that can take care of high effect and abrasion. And it continually is used to make superior die, screw dies, reamer, milling cutter, iron head, punch, complex shape tools with excessive sturdiness.

And the hardness of them is sixty six±1hrc and sixty seven±1 hrc. M35 steel round bar plate sheet homes and chemical composition as under.

It is easy to do the hot and bloodless process. After the quenching and tempering, the hardness might be the same as m42 steel.

| Physical Properties | Imperial | Metric |

|---|---|---|

| Density | 0.294 lb/in³ | 8.14 g/cm³ |

M35 Steel Annealing Process.

If you case it up for the annealing after the forging, you will get a higher result. In case you can not try this, simply make it bloodless to the indoor temperature then make it in.

In case you can not try this, simply make it bloodless to the indoor temperature then make it in. About the annealing system, simply placed it within the range with the temperature that is lower than 500℃.

Then heat to 840-860℃, preserve the temperature for 4 to 5 hours. That allows you to prevent oxidative decarburization show up, the annealing have to be careful.

And there is an easy manner can try this. Just put a few wooden dirt to the annealing furnace. Furnace cooling to 500℃ underneath than out of it. Cooling slowly inside the annealing furnace. After the annealing, its hardness is lower than 255hb.

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |