1.2311 Steel Plate 310 x 160(DIN 40CrMnMo7, AISI P20, SAE P20)

- Description

- Size Guide

Description

1.2311 Steel Plate 310 x 160 / DIN 40CrMnMo7 / AISI P20 / SAE P20.

Buy European and American quality steel in India 1.2311 Steel Plate 310 x 160 | DIN 40CrMnMo7 | AISI P20 | SAE P20.

We have European and American quality steel grades DIN 1.2311 Steel Plate (DIN 40CrMnMo7, AISI P20, SAE P20).

always buy high-quality steel with a Non-destructive lab certificate.

| DESIGNATION | |

|---|---|

| AFNOR: | 40 CMD 8 |

| UNI: | 35 CrMo 8 KU |

| AISI: | P20 |

| download | 40 CrMnMo 7 |

| CHEMICAL COMPOSITION: | |

|---|---|

| C | 0.40 |

| Si | 0.40 |

| Mn | 1.50 |

| Cr | 1.90 |

| Mo | 0.20 |

STRENGTH:

280 – 325 HB

(≈ 950 – 1100 N/mm²)

THERMAL CONDUCTIVITY AT 100 °C:

35 W/m K

CHARACTER:

alloyed and pre-toughened tool steel, especially suitable for polishing and nitriding; high dimensional stability.

APPLICATION:

cavity plates, inserts, and high-tensile machine parts.

TREATMENT BY

possible:

Etching, EDM

Polishing:

excellent polishing; for higher surface requirements we recommend steel for through hardening

Nitriding:

increases the steel’s wear resistance

Hard chroming:

particularly increases the steel’s wear resistance and corrosion resistance.

HEAT TREATMENT:

already pre-toughened; usually, no heat treatment is required.

Nitriding:

Before nitriding, stress-relief annealing is recommended at 580 °C. (Meusburger standard).

Hard chroming:-

After the hard chroming, the mold must be annealed for about 3 to 4 hours at 180 °C to avoid brittle fractures from hydrogen.

Hardening:- 840 to 860 °C.

Cooling:-

to 180 °C/220 °C in an oil/hot bath, then in the air to about 100 °C obtainable hardness: 52 HRC.

Tempering:-

Slow heating to tempering temperature immediately after hardening. Minimum time in a furnace: 1 hour per 25 mm part thickness.

Annealing graph:-

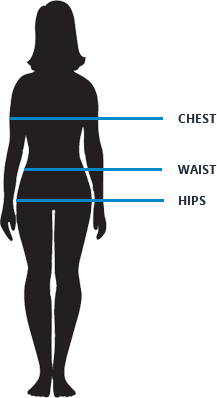

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |