- Description

Description

What is Alloyed Carbon Steels?

Alloyed carbon steels are an essential category of steels that incorporate additional alloying elements to enhance their mechanical properties. These steels offer superior strength, hardness, wear resistance, and corrosion resistance compared to plain carbon steels. They are widely used in industries such as automotive, construction, aerospace, and manufacturing. This article explores the composition, properties, classifications, advantages, applications, and future trends of alloyed carbon steels.

What is the Composition of Alloyed Carbon Steels?

Alloyed carbon steels are primarily composed of iron and carbon, with additional alloying elements such as:

- Manganese (Mn): Improves strength, toughness, and hardenability.

- Chromium (Cr): Enhances wear and corrosion resistance.

- Nickel (Ni): Adds toughness and resistance to impact.

- Molybdenum (Mo): Increases strength, hardness, and high-temperature stability.

- Vanadium (V): Refines grain structure and boosts wear resistance.

- Silicon (Si): Enhances strength and oxidation resistance.

The specific composition varies depending on the intended application and required mechanical properties.

What are the Classification of Alloyed Carbon Steels?

Alloyed carbon steels can be classified based on the alloying element concentration and heat treatment processes. The main categories include:

1.Low-Alloy Carbon Steels

Low-alloy carbon steels contain small amounts (typically less than 5%) of alloying elements. These steels provide improved strength and toughness without significantly increasing production costs. Examples include structural steels used in bridges, pipelines, and machinery components.

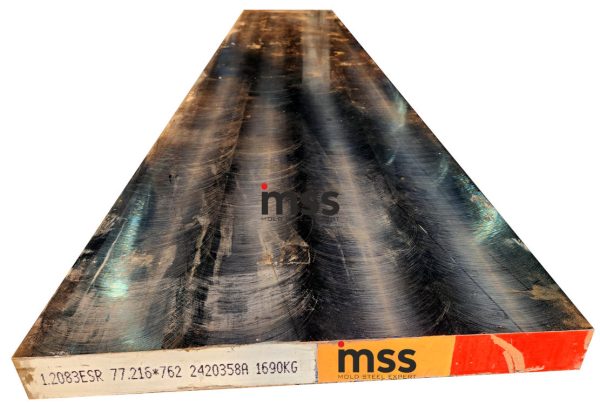

2.High-Alloy Carbon Steels

High-alloy carbon steels contain higher amounts of alloying elements, often exceeding 5%. These steels offer superior hardness, wear resistance, and corrosion resistance. Examples include tool steels used in cutting tools, dies, and molds.

What are the Properties of Alloyed Carbon Steels?

The presence of alloying elements significantly influences the properties of carbon steels. Key properties include:

1. Enhanced Strength and Toughness

Alloyed carbon steels exhibit higher tensile strength and toughness, making them suitable for heavy-load applications in construction and transportation.

2. Improved Wear and Abrasion Resistance

Elements such as chromium and vanadium enhance wear resistance, making these steels ideal for high-friction environments such as mining and manufacturing.

3. Superior Corrosion Resistance

Nickel and chromium improve resistance to oxidation and rust, extending the lifespan of components in marine and chemical industries.

4. Increased Hardness and Hardenability

Molybdenum and manganese increase the hardness of alloyed carbon steels, enabling their use in tools, dies, and cutting equipment.

5. Heat Resistance

Alloyed carbon steels can withstand high temperatures, making them suitable for applications in aerospace and power generation.

What are the Advantages of Alloyed Carbon Steels?

Alloyed carbon steels offer several advantages over plain carbon steels:

- Greater Strength-to-Weight Ratio: Ideal for lightweight yet durable structures.

- Extended Service Life: Reduced wear and corrosion improve longevity.

- Customization: Alloying elements can be tailored to meet specific application requirements.

- Versatile Applications: Used in multiple industries, from automotive to defense.

- Cost-Effective: Despite a higher initial cost, reduced maintenance expenses make them economically viable.

What are the Applications of Alloyed Carbon Steels?

Alloyed carbon steels are used in various industries due to their superior mechanical properties. Some key applications include:

1. Automotive Industry

- Used in manufacturing gears, axles, crankshafts, and connecting rods.

- Enhances fuel efficiency and vehicle performance due to lightweight yet strong materials.

2. Construction and Infrastructure

- Utilized in bridges, buildings, and pipelines for structural integrity.

- Provides resistance against environmental factors like corrosion and wear.

3. Aerospace Industry

- Used in aircraft landing gears, turbine blades, and structural components.

- Provides strength and heat resistance required for high-altitude performance.

4. Manufacturing and Industrial Machinery

- Applied in tools, dies, and machine parts exposed to heavy loads and friction.

- Ensures durability and efficiency in industrial processes.

5. Energy and Power Generation

- Utilized in power plants, nuclear reactors, and wind turbines.

- Withstands high temperatures and pressure conditions.

What is the Heat Treatment and Processing of Alloyed Carbon Steel?

Heat treatment plays a crucial role in optimizing the properties of alloyed carbon steels. Common heat treatment methods include:

1. Annealing

- Softens the steel, improving machinability and stress relief.

- Reduces hardness for easier forming and shaping.

2. Quenching and Tempering

- Enhances hardness and toughness by controlled heating and rapid cooling.

- Tempering reduces brittleness while maintaining strength.

3. Normalizing

- Refines the grain structure, improving mechanical properties.

- Enhances strength and uniformity of the steel.

4. Case Hardening

- Increases surface hardness while maintaining a tough core.

- Used in gears, bearings, and automotive components.

What are the Challenges and Limitations of Alloyed Carbon Steel?

Despite their numerous benefits, alloyed carbon steels have some challenges:

- Higher Cost: The addition of alloying elements increases production expenses.

- Complex Processing: Specialized heat treatment and machining processes are required.

- Brittleness: Excessive hardness can lead to brittleness in some applications.

- Corrosion Sensitivity: Certain alloys require protective coatings to prevent rust.

Future Trends in Alloyed Carbon Steel

Advancements in materials science continue to drive innovations in alloyed carbon steels. Key future trends include:

- Development of Ultra-High-Strength Steels (UHSS): Enhanced performance for automotive and aerospace applications.

- Advanced Coating Technologies: Improved corrosion resistance and wear protection.

- Lightweight and High-Performance Alloys: Focus on sustainability and energy efficiency.

- Integration with Additive Manufacturing: 3D printing of custom alloyed steel components.

- Smart Steels: Incorporation of sensors and self-healing properties for enhanced durability.

Conclusion

Alloyed carbon steel play a critical role in various industries due to their superior strength, hardness, and durability. Their ability to withstand wear, corrosion, and high temperatures makes them indispensable in applications ranging from automotive to aerospace. While challenges exist, continuous advancements in metallurgy are driving the development of more efficient and high-performance alloyed carbon steels. With ongoing research and technological improvements, the future of alloyed carbon steels remains promising, ensuring their continued relevance in modern engineering and manufacturing.