DIN 1.2738 Steel, P20 Steel Plates a Versatile Tool Steel for Plastic Moulding

- Description

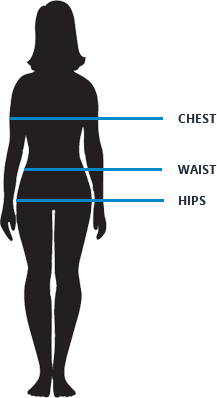

- Size Guide

Description

DIN 1.2738 Steel/P20 Steel :- The Versatile Tool Steel for Precision Plastic Molding Applications.

DIN 1.2738 steel, also known as 40CrMnNiMo8-6-4, is a premium-grade pre-hardened tool steel renowned for its excellent machinability, toughness, and uniform hardness.

Designed specifically for large plastic mold applications, it has become an industry standard in toolmaking for plastic injection molding, die casting, and other precision tools.

Its versatility and unique properties make it the material of choice for manufacturers aiming for durability, high performance, and cost-effectiveness.

This article provides an in-depth analysis of DIN 1.2738 plastic mold steel, including its properties, applications, and advantages, as well as its role in modern manufacturing industries.

What is DIN 1.2738 Steel?

DIN 1.2738 tool steel is a modified version of DIN 1.2311, with added nickel for improved hardness and toughness throughout its structure.

It is a pre-hardened steel, meaning it is delivered with a uniform hardness level (approximately 280–320 HB) that eliminates the need for additional heat treatment.

This property makes DIN 1.2738 highly machinable and cost-efficient, ideal for producing molds that demand dimensional accuracy and long service life.

With a chemical composition tailored to optimize hardness, toughness, and corrosion resistance, DIN 1.2738 steel is widely used in manufacturing plastic molds for automotive parts, household appliances, and more.

Chemical Composition of DIN 1.2738 Steel/P20 steel.

DIN 1.2738 steel’s chemical composition ensures a balanced combination of strength, wear resistance, and toughness. Below is the approximate composition:

Carbon (C): 0.37 – 0.43%

Chromium (Cr): 1.80 – 2.10%

Nickel (Ni): 0.90 – 1.20%

Manganese (Mn): 0.60 – 1.00%

Molybdenum (Mo): 0.15 – 0.25%

Silicon (Si): 0.20 – 0.40%

Sulfur (S): ≤ 0.03%

This composition enhances the steel’s mechanical and thermal properties, ensuring consistent performance in demanding applications.

Properties of DIN 1.2738 Steel.

DIN 1.2738 steel offers a variety of properties that make it highly suitable for tooling and mold-making applications:

1. Uniform Hardness

DIN 1.2738 is delivered in a pre-hardened state with a consistent hardness level of approximately 280–320 HB. This eliminates the need for additional heat treatment, saving time and costs during the manufacturing process.

2. Good Toughness

The steel exhibits excellent toughness, allowing it to withstand high mechanical stresses without cracking or deforming. This property is critical for large molds used in industries like automotive manufacturing.

3. High Machinability

Thanks to its pre-hardened state, DIN 1.2738 is easy to machine, enabling faster production cycles and precise detailing. Its machinability makes it a cost-effective solution for mold manufacturers.

4. Wear Resistance

The addition of chromium and nickel improves the steel’s wear resistance, ensuring that molds and tools maintain their structural integrity even under prolonged use.

5. Polishability

DIN 1.2738 can achieve excellent surface finishes, making it ideal for molds that produce visually appealing plastic parts, such as automotive interiors and consumer goods.

6. Dimensional Stability

With its uniform hardness and balanced composition, DIN 1.2738 steel exhibits excellent dimensional stability, ensuring accuracy in large molds and reducing the risk of warping or distortion.

Applications of DIN 1.2738 Steel

The versatility of DIN 1.2738 steel makes it suitable for a wide range of applications, particularly in industries that require precision tooling and high-performance molds:

1. Plastic Injection Molds

DIN 1.2738 is widely used for manufacturing injection molds, especially for large plastic components. It is commonly employed in molds for automotive parts, packaging, and household appliances.

2. Blow Molding

The steel’s uniform hardness and wear resistance make it a popular choice for blow molds used in the production of hollow plastic products such as bottles and containers.

3. Die Casting Molds

DIN 1.2738 is used for die casting molds that require high durability and thermal stability. Its toughness ensures reliable performance under high temperatures and mechanical stresses.

4. Automotive Applications

The automotive industry relies heavily on DIN 1.2738 for molds that produce parts such as dashboards, bumpers, and other large components. Its toughness and dimensional stability ensure high-quality results.

5. Consumer Goods

The steel’s ability to achieve a high polish finish makes it ideal for molds used in producing visually appealing consumer goods, such as electronics housings and cosmetic packaging.

Advantages of Using DIN 1.2738 Steel

DIN 1.2738 steel offers numerous advantages that make it a preferred material for tooling and mold-making applications:

1. Cost-Effectiveness

As a pre-hardened steel, DIN 1.2738 eliminates the need for additional heat treatment, reducing production costs and lead times.

2. High Durability

The steel’s wear resistance and toughness ensure a long service life for molds and tools, minimizing maintenance and replacement costs.

3. Versatility

DIN 1.2738’s properties make it suitable for a wide range of applications, from automotive molds to consumer goods. Its versatility reduces the need to source multiple materials for different projects.

4. Excellent Surface Finish

The steel’s polishability allows manufacturers to produce molds that create parts with smooth, high-quality finishes, enhancing the aesthetic appeal of the final product.

5. Consistent Performance

With its uniform hardness and dimensional stability, DIN 1.2738 delivers consistent results in large-scale applications, ensuring accuracy and reliability.

Heat Treatment of DIN 1.2738 Steel.

Although DIN 1.2738 is delivered in a pre-hardened state, additional heat treatment can be performed for specific applications requiring higher hardness or tailored properties:

Annealing:

To improve machinability, the steel can be annealed by heating it to approximately 650–700°C and slowly cooling.

Nitriding: For enhanced surface hardness and wear resistance, nitriding can be applied to DIN 1.2738.

Why Choose DIN 1.2738 Steel?

DIN 1.2738 steel is the material of choice for manufacturers who demand high performance, durability, and cost-efficiency in their tooling and mold-making processes.

Its combination of toughness, wear resistance, and machinability makes it ideal for producing large molds and precision tools that meet the rigorous standards of industries like automotive, packaging, and consumer goods.

When compared to other grades, DIN 1.2738 stands out for its consistent hardness, reduced need for heat treatment, and ability to achieve excellent surface finishes.

These qualities not only save time and money but also ensure high-quality results for end users.

Conclusion:-

DIN 1.2738 steel is a high-performance, pre-hardened tool steel designed to meet the demands of modern manufacturing.

Its exceptional toughness, machinability, and uniform hardness make it a top choice for producing large molds and precision tools.

Whether you’re working in the automotive, consumer goods, or packaging industry, DIN 1.2738 delivers the performance, reliability, and cost-effectiveness needed to succeed.

By choosing DIN 1.2738 steel, manufacturers can achieve long-lasting results, reduce production costs, and deliver high-quality products that meet the evolving needs of their industries.

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |