C45 Steel Plates 610x205mm, a high-quality medium-carbon steel grade Delhi

- Description

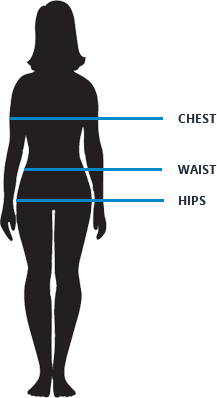

- Size Guide

Description

C45 Steel Plates 610x205mm, a high-quality medium-carbon steel grade Delhi.

AISI 1045 steel is high-quality medium-carbon steel with high strength.

It also can be called JIS S45C and DIN 1.1191.

most common alternatives for C45 Steel are the followings JIS S45C, 1045 Steel, CK45, DIN 1.1191.

It is usually used in normalized conditions because of its bad hardenability.

It needs to be quenching and tempering treatment to get higher mechanical performance.

C45 Steel Plates are used to manufacture machine parts with high strength requirements.

you can use it in making industrial parts like Mould bases, Plastic molds, gears, shafts, piston pins, etc.

1045 Steel round bar sheet plate properties and heat treat as below.

C45 Steel Plates Characteristics:-

It is carbon steel and has great weldability and machinability.

After normalized and hot-rolled, it will get high strength and impact properties.

It has a low hardenability and a critical hardenability diameter is 12-17mm in the water.

And there tends to crack when water is quenching.

You can use hydrogen welding and argon arc welding are good for it.

but when you use the gas welding is not good on the C45 Steel, JIS S45C, 1045 Steel, EN8 Steel, EN8D Steel, DIN 1.1191 Plates.

It is required to preheat before the welding, and stress relief annealing should be performed after welding.

a rapid quench for increased hardness throughout the material.

C45 Steel

C45 Steel, JIS S45C, 1045 Steel, EN8 Steel, EN8D Steel, DIN 1.1191 Plates Rounds Chemical Composition Properties are given below.

C45 Steel Plates, JIS S45C, 1045 Steel, EN8 Steel, EN8D Steel, DIN 1.1191 Chemical Composition Properties

C45 Steel (Plates Rounds, bars ), JIS S45C, 1045 Steel, EN8 Steel, EN8D Steel, DIN 1.1191Chemical Composition Properties are given below.| STANDARD | C % | Mn % | Si % | P % | S % | Cr % | Mo % | Ni % | V % | W % | CO % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C45 Steel | 0.42 ~ 0.50 | 0.50 ~ 0.80 | 0.15 ~ 0.40 | 0.045% max | 0.045% max | ~ | ~ | ~ | ~ | ~ | ~ |

| JIS S45C | 0.42 ~ 0.48 | 0.60 ~ 0.90 | 0.15 ~ 0.35 | 0.030% max | 0.035% max | ~ | ~ | ~ | ~ | ~ | ~ |

| EN8 Steel | 0.35 ~ 0.45 | 0.60 ~1.0 | 0.05 ~ 0.35 | 0.15 ~ 0.60 | 0.15 ~ 0.60 | ~ | ~ | ~ | ~ | ~ | ~ |

| EN8D Steel | 0.40 ~ 0.45 | 0.70 ~ 0.90 | 0.15 ~ 0.40 | 0.045% max | 0.045% max | ~ | ~ | ~ | ~ | ~ | ~ |

| EN9 Steel | 0.50 ~ 0.60 | 0.60 ~ 0.80 | 0.05 ~ 0.35 | 0.040% max | 0.040% max | ~ | ~ | ~ | ~ | ~ | ~ |

| 20MNCR5 | 0.17 ~ 0.22 | 1.10 ~ 1.40 | 0.15 ~ 0.40 | 0.035% max | 0.035% max | 1.0 ~ 1.30 | ~ | ~ | ~ | ~ | ~ |

| DIN 1.1191 | 0.42 ~ 0.50 | 0.50 ~ 0.80 | ≤0.40 | ≤0.035 | ≤0.035 | ~ | ~ | ~ | ~ | ~ | ~ |

| CK45 | 0.42 ~ 0.50 | 0.50 ~ 0.80 | ≤0.40 | ≤0.035 | ≤0.035 | ~ | ~ | ~ | ~ | ~ | ~ |

| 1045 Steel | 0.43~0.50 | 0.60 ~ 0.90 | 0.15 ~ 0.40 | ≤0.040 | ≤0.050 | ~ | ~ | ~ | ~ | ~ | ~ |

| EN 10083/2-2006 | 0.42 ~ 0.50 | 0.50 ~ 0.80 | 0.15 ~ 0.40 | 0.045% max | 0.045% max | ≤0.40 | ≤0.10 | ≤0.40 | ~ | ~ | ~ |

| JIS G4051-2009 | 0.42 ~ 0.48 | 0.50 ~ 0.80 | 0.10 ~ 0.40 | 0.035% max | 0.035% max | ~ | ~ | ≤0.20 | ~ | ~ | ~ |

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |