1.2085 Steel Plastic mould Steel

| Usage/Application | Automobile Industry |

|---|---|

| Material | Mould Steel Din 1.2085 |

| Surface Finish | polished |

| Dimension | customized |

| Density | customized |

| Shape | Round |

- Description

- Size Guide

Description

Product Description

he moulds used for plastic processing are very diverse in their functionality and the demands made on them. The correct choice and treatment of the steel grade are decisively influential on the quality and resulting profitability of plastic production. So as to ensure the client’s demands are met, we rely on a highly experienced group of specialists in the steels-for-plastic-moulding area. Together with the mould manufacturers, they constitute a perfectly coordinated team to determine which steel grade and quality are most appropriate to the individual profile demands as characterized by the final plastic product.

Product Specification

UseA A A A A A A

1. corrosion resistanceA A

2. wear resistance of high quality plastic mould

3. transparent plastic mould.

Heat TreatmentA A A A A A A

annealed, 229HBS max(optional)/after Q+T, hardness 28-32HRC(optional)

Melting ProcessA

1. EAF: Electric Furnace+LF+VD(Optional)

2. ESR: A Electric Furnace+LF+VD+Eleroslag Remelted(Optional)

UT Class

According to Standard of SEP 1921/84,100% Volume, Level C/c, D/d or E/e

Tolerance on Quantity

+/-10% Per Size

Documents

1.A Packing List

2. Invoice

3. CO.

4. Bill of Loading

5. Shipping Advice

6. Mill Test Certificate

7. The other files as you requested

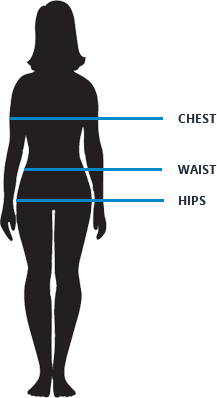

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |