1.2379 D2 steel , High speed , round 110mm, 120mm

- Description

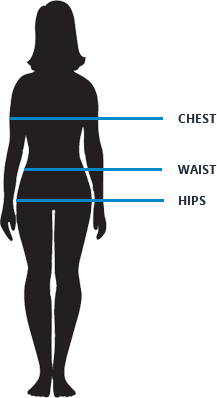

- Size Guide

Description

1.2379 D2 steel , High speed , round 110mm, 120mm

D2 steel/ 1.2379

D2 steel/ 1.2379 steel is excessive put on-resistant and micro-deformation cold mould metal, belong to the wind harden tool steel.

The mass fraction of the carbon is as high as 1.7%, the mass fraction of chromium is as high as 11.8%.

the hardness after heat remedy can attain 60 HCR, ductility, longevity, rust-resistant potential is getting weak relatively.

the steel surface is also difficult to make replicate sharpening processing.

With the improvement of Cold stamping products to high precision, high efficiency and numerous types.

it is required that die steel have better wear resistance and longevity.

As compared with cr12mov steel, at the chemical composition of the steel elevated Mo, v, changed the steel casting company, improved the morphology of austenite dish, robust longevity, and abrasion resistance is better than that of cr12mov steel.

stepped forward the provider lifestyles of the mold.

Because the yield point and plastic deformation resistance of the steel are better than that of cr12mov steel, its forging overall performance and thermoplastic formability are barely worse than that of cr12mov steel.

Chemical Composition.

| Molybdenum | Carbon | Phosphorus | sulfur | Chromium | Vanadium | Manganese | silicon | Carbon | |||

| 0.7-1.2 | 1.4-1.6 | 0.03Max | 0.03max | 11-13 | 0.5-1.1 | 0.1-0.6 | 0.1-0.6 | 1.4-1.6 | |||

Applications of D2 steel/ 1.2379

D2 steel is appropriate for complex tool steel with possible deformation, all styles of cold stamping die with high abrasion resistance and lengthy lifestyles, bloodless cutting aspect and thread rolling plate.

Cold extrusion forming, drawing die, stainless-steel sheet and high hardness material blanking die.

1) Compared with cr12mov steel, the rolling wheel and rancid-platform adjustment plate cold punch product of d2 steel can increase the provider existence via five-6 times.

2) To enhance the d2 cold work mold provider existence of the flat steel rolled products, undertake the approach of including rare earth, the wear and tear resistance.

effect sturdiness of steel is significantly stepped forward, if you want to obtain the cause of prolonging the provider lifestyles of round mold flat steel rolled products.

3) quenching hardness 56~58hrc For deep drawing mold of fridge compressor rear cover.

4) As the content material of v and Mo in d2 steel is higher than that of cr12mov steel, it has higher complete overall performance, and conventional cr12mov steel can be gradually replaced.

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |